Advantages

Compressed air of high reliability and quality

Compressed air of high reliability and quality- Superior energy efficiency

- High flexibility

- Reduced footprint

- Reduced maintenance costs

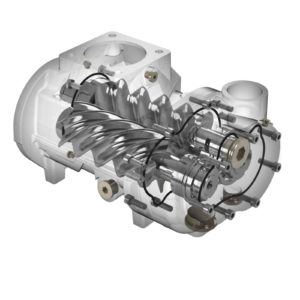

Energy efficiency was the key factor in the development of this recent compressor range. The self-manufactured compressor element, high efficiency and low rotation speed significantly reduces energy costs. In addition, the innovative design of the fail-safe shaft seal, integrated oil filter and oil regulating valve allows external hoses to be minimised to ensure maximum levels of quality and reliability.

The range consists of constant and variable speed (RS) models and features an integrated refrigerant dryer and heat recovery system for improved efficiency and energy savings.

Compressed air of high reliability and quality

Compressed air of high reliability and quality A modern design based on quality components gives operators the reliability they need from their compressed air source. The high-capacity compressor element and the efficient IE3 electric motor are the key elements that ensure maximum performance levels. The use of the high efficiency filter separator ensures the delivery of the highest quality air (oil particle accumulation < 3 ppm) to the compressed air network. The fan, with a quiet, high-efficiency thermostatically controlled motor, allows the compressor to be installed in the workplace and to use ducts of maximum length without the need for additional help.

A modern design based on quality components gives operators the reliability they need from their compressed air source. The high-capacity compressor element and the efficient IE3 electric motor are the key elements that ensure maximum performance levels. The use of the high efficiency filter separator ensures the delivery of the highest quality air (oil particle accumulation < 3 ppm) to the compressed air network. The fan, with a quiet, high-efficiency thermostatically controlled motor, allows the compressor to be installed in the workplace and to use ducts of maximum length without the need for additional help.

CompAir L Series – L23 – L29 –

Technical Specifications

L23 – L29: constant speed

| Compressor model | Nominal pressure [bar g] | Drive motor

[kW] |

FAD 1]

[m3/min]

|

Noise level2][dB(A)] | Weight

[kg]

|

Dimensions l length x width x height[mm] |

|---|---|---|---|---|---|---|

| L23 | 7,5 | 22 | 4,16 | 67 | 650 | 1345 x 880 x 1612 |

| 10 | 22 | 3,45 | 67 | 650 | 1345 x 880 x 1612 | |

| 13 | 22 | 2,98 | 67 | 650 | 1345 x 880 x 1612 | |

| L26 | 7,5 | 26 | 4,84 | 68 | 677 | 1345 x 880 x 1612 |

| 10 | 26 | 4,13 | 68 | 677 | 1345 x 880 x 1612 | |

| 13 | 26 | 3,44 | 68 | 677 | 1345 x 880 x 1612 | |

| L29 | 7,5 | 30 | 5,52 | 69 | 681 | 1345 x 880 x 1612 |

| 10 | 30 | 4,81 | 69 | 681 | 1345 x 880 x 1612 | |

| 13 | 30 | 4,12 | 69 | 681 | 1345 x 880 x 1612 |

| Compressor model | Refrigerant dryer | Pressure dew point 3]

[°C] |

Weight

[kg]

|

Dimensions

l length x width x height[mm] |

|---|---|---|---|---|

| L23F | F29E | 5 | 840 | 1675 x 880 x 1612 |

| L26F | F29E | 5 | 867 | 1675 x 880 x 1612 |

| L29F | F29E | 5 | 871 | 1675 x 880 x 1612 |

| Compressor model | Pressure

[bar g] |

Drive motor

[kW] |

FAD1] a 7,5 bar g

[m3/min]

|

FAD1] a 10 bar g

[m3/min]

|

FAD1] a 13 bar g

[m3/min]

|

Noise level at 70% load 2], 1 m[dB(A)] | Weight

[kg]

|

Dimensions

largo x ancho x alto

[mm]

|

|

|---|---|---|---|---|---|---|---|---|---|

| Mín. | Máx. | ||||||||

| L23RS | 5 | 13 | 22 | 1,11 – 4,12 | 1,03 – 3,50 | 1,35 – 2,89 | 68 | 681 | 1345 x 880 x 1612 |

| L26RS | 5 | 13 | 26 | 1,11 – 4,78 | 1,03 – 4,10 | 0,92 – 3,56 | 69 | 708 | 1345 x 880 x 1612 |

| L29RS | 5 | 13 | 30 | 1,11 – 5,41 | 1,03 – 4,50 | 0,92 – 3,82 | 69 | 712 | 1345 x 880 x 1612 |

| Compressor model | Refrigerant dryer | Pressure dew point 3][°C] | Weight

[kg]

|

Dimensions

length x width x height

[mm]

|

|---|---|---|---|---|

| L23RSF | F29E | 5 | 871 | 1675 x 880 x 1612 |

| L26RSF | F29E | 5 | 898 | 1675 x 880 x 1612 |

| L29RSF | F29E | 5 | 902 | 1675 x 880 x 1612 |

1 Data measured and defined according to ISO1217, fourth edition, Annexes C and E, under the following conditions:

Air inlet pressure 1 bar A / 14.5 psi; Air inlet temperature 20 °C / 68 °F; Humidity 0% (dry)

2 Measurements under free field conditions according to ISO 2151, tolerance ± 3dB(A)

3 The refrigerant dryer requires an independent power supply. Data refer to DIN ISO 7183, 8573-1:2001 (class 4, pressure dew point 3 °C). For more information, refer to the refrigerant dryer documentation.