Advantages

An investment

profitable

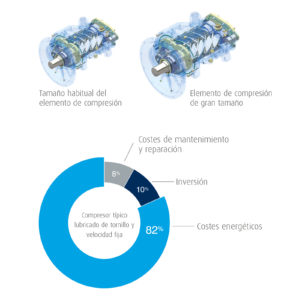

The E models of the L series feature an extra large airend, which has an optimised maximum rotor speed, saving up to 6% energy. The most expensive component of a compressor is the energy required to run it. Reducing energy cost significantly affects the total cost of ownership. The additional investment cost for this range of super efficient compressors will be paid in less than 12 months. The extra large airend has greater durability.

Speed regulated compressors

CompAir’s variable speed compressors can efficiently and reliably manage the variable air demand of most plants. The use of variable speed technology can significantly reduce the annual cost of ownership.

CompAir’s regulated speed brings advantages

The L-RS series products are designed for maximum efficiency throughout the operating interval.

Wide regulation range – The absence of cycles means considerable energy savings.

Motor – Coupling – Airend design – High efficiency throughout the flow range.